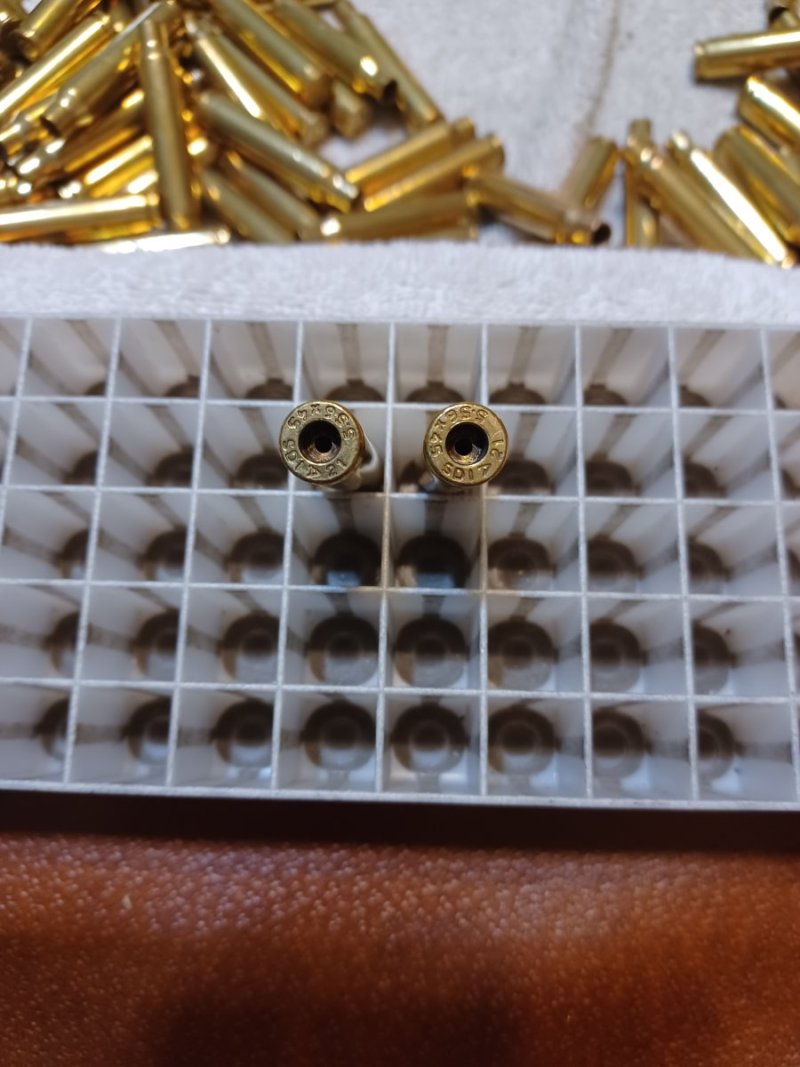

I pick up some once fired Winchester 30-06 ammo from other odt member, the brass looks great, it wasn’t very dirty still shiny,

I cleaned it and the lubed and tried to run it through my Forster die and it won’t go! It gets stuck I almost broke the table trying to pull the handle, I cleaned the die, polished the inside of it, still the same tried the empty case in two rifles, both would not close with bolt, Remington, herters, armscor all work great, has anyone run into this problem?

I cleaned it and the lubed and tried to run it through my Forster die and it won’t go! It gets stuck I almost broke the table trying to pull the handle, I cleaned the die, polished the inside of it, still the same tried the empty case in two rifles, both would not close with bolt, Remington, herters, armscor all work great, has anyone run into this problem?