I'm reaching out to anyone that casts their own bullets in the coastal GA area. I would like to come and watch your casting process for some hands on experience. I've watched tons of YouTube videos and I feel like I'm missing out on some details. Before I invest in equipment, I'd like to get some opinions other than online product reviews. As well as see your setup and what works for you.

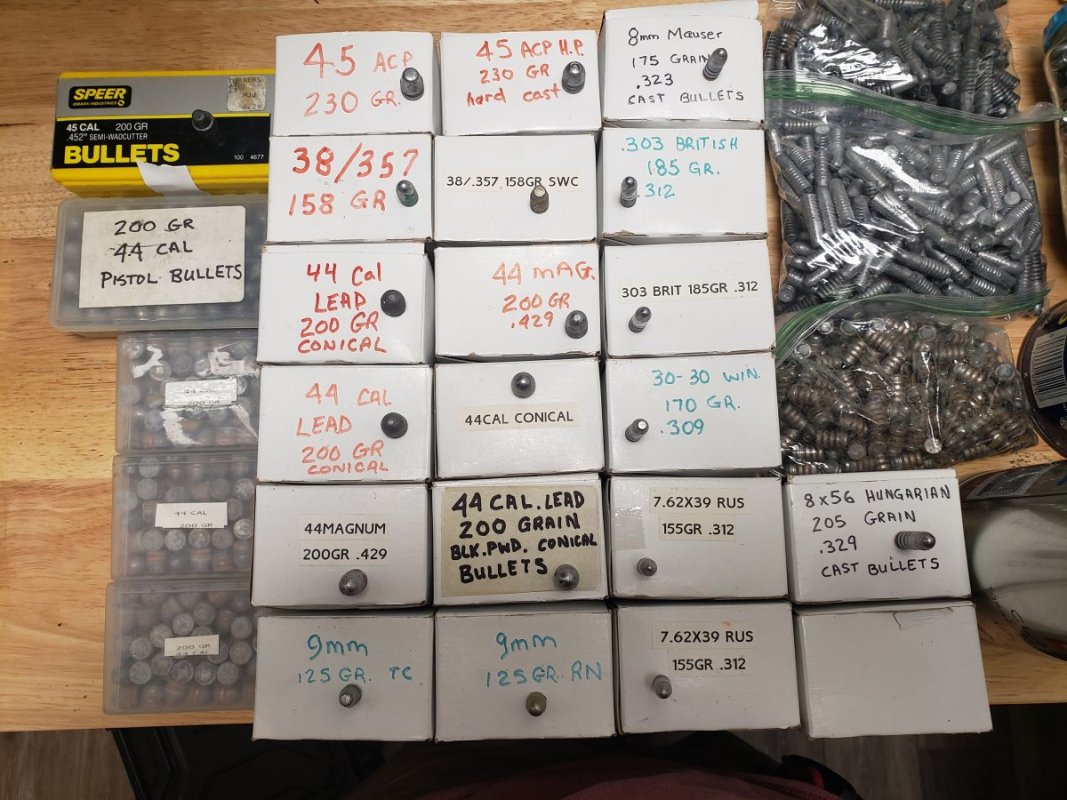

I already reload rifle and pistol in many calibers. I want to start casting for my 45-70 and 375 H&H mag.

Thanks.

I already reload rifle and pistol in many calibers. I want to start casting for my 45-70 and 375 H&H mag.

Thanks.