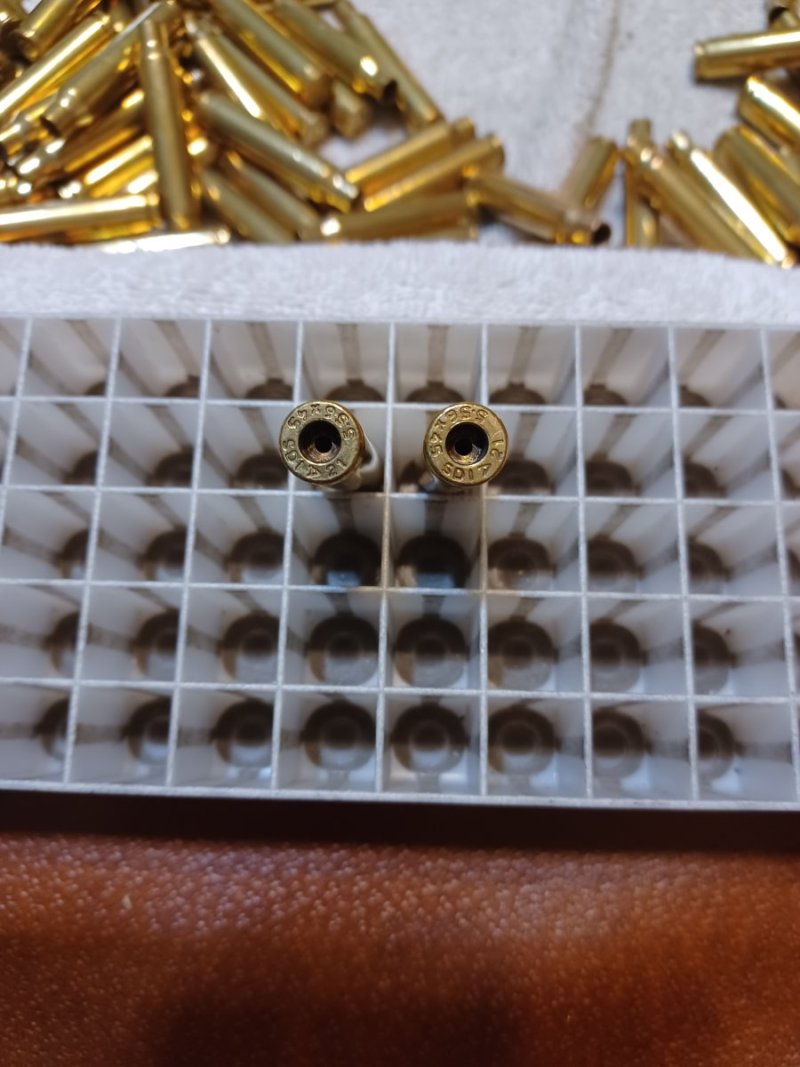

on a regular basis nothing. I try to roll the neck on the lube pad.

Keep the case neck off the pad, you don't want lube on the neck. For neck internals I will take a q tip and dip it in the lube and run it around the inside of the neck, about 5 cases worth before relubing the q tip.