This is part I of a series where I show how one of our Onyx rifles is built. In this series I will take the readers step by step through the entire process from removing the old bolt knob all the way to final testing and acceptance of a completed rifle.

The Onyx consists of the following:

Trued and blueprinted Remington 700 action

Shilen 5.5 contour match grade barrel

Timney Trigger

EGW Scope base

Fort Daniel Ratio Micro bolt knob

Bell & Carlson Medalist Tactical stock

Graphite Black Cerakote

In this installment the old bolt knob will be removed and a new Ratio Micro knob will be fitted.

L to R: Bolt, Bolt Takedown Tool, Bolt Holding Fixture, Hollow Mill, 5/16 End Mill

1961 J Series Bridgeport Milling Machine. American Iron!

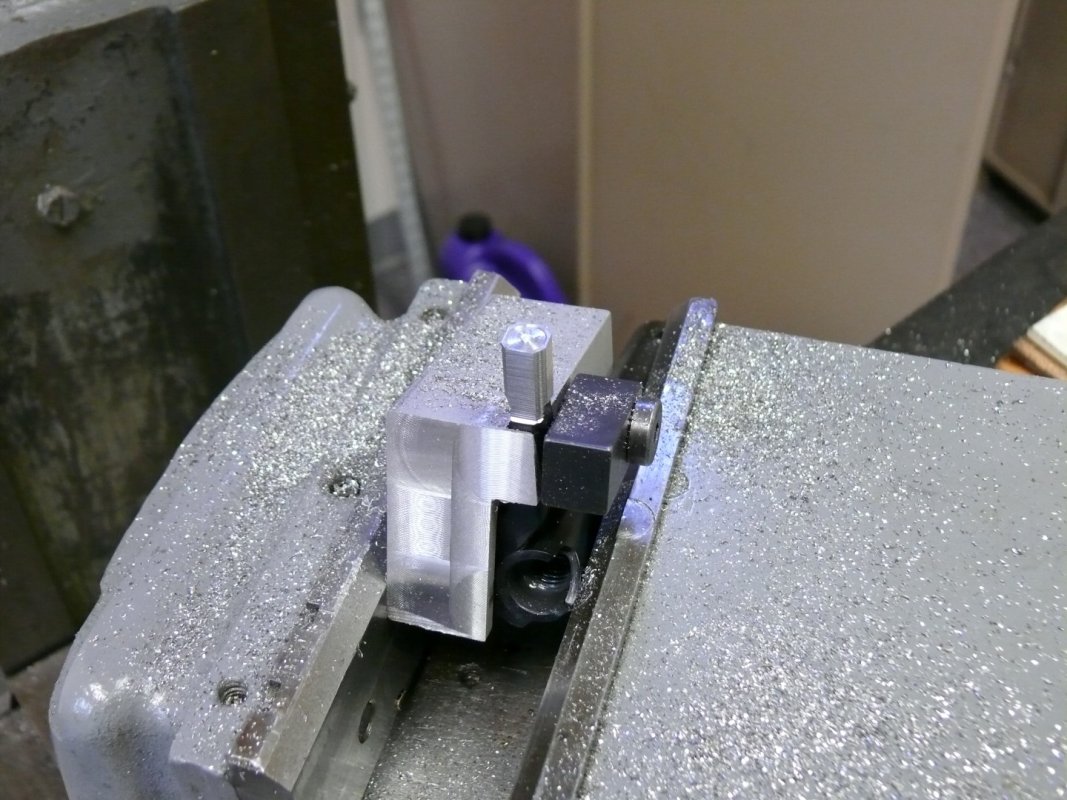

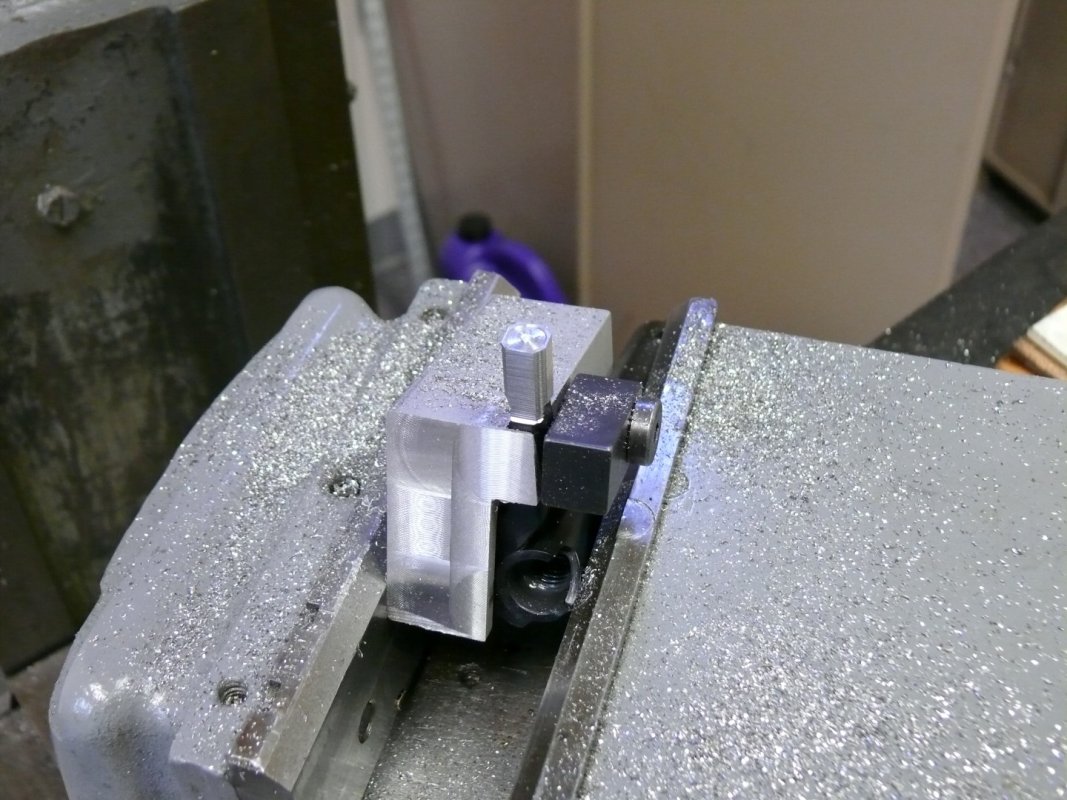

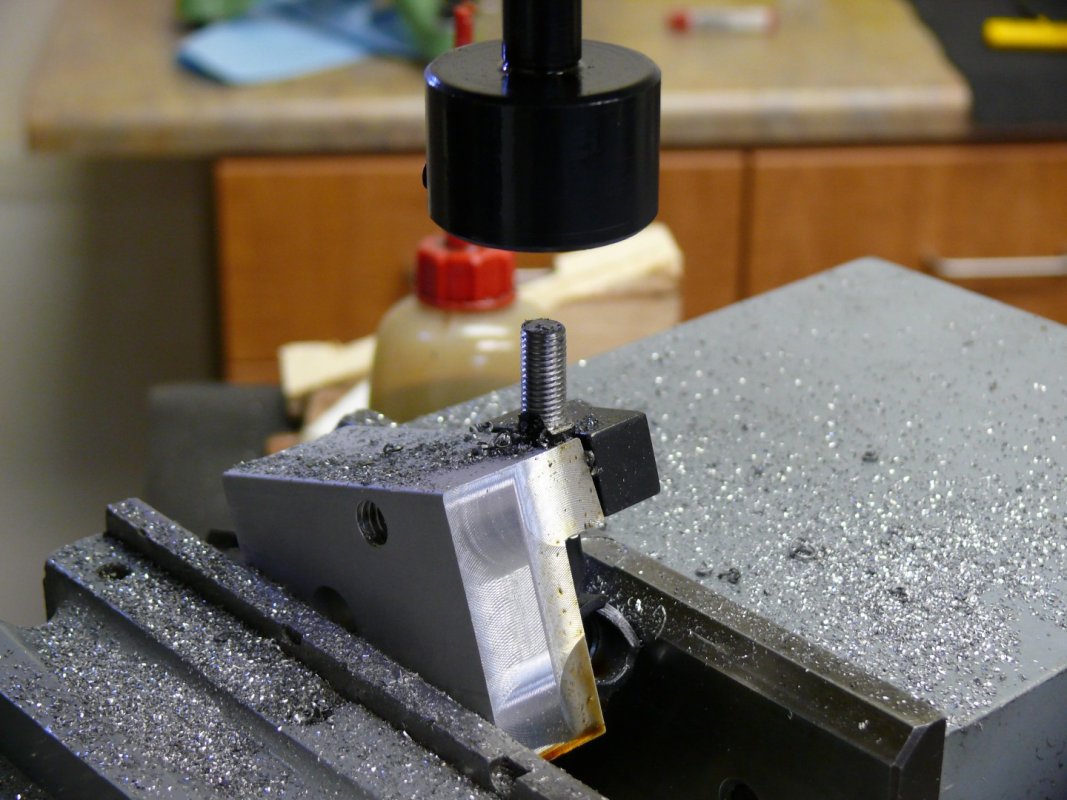

Bolt and fixture in milling machine vise with angle block that provides a 11 degree sweep for the bolt handle. A straight handle can also be done if the customer requests it.

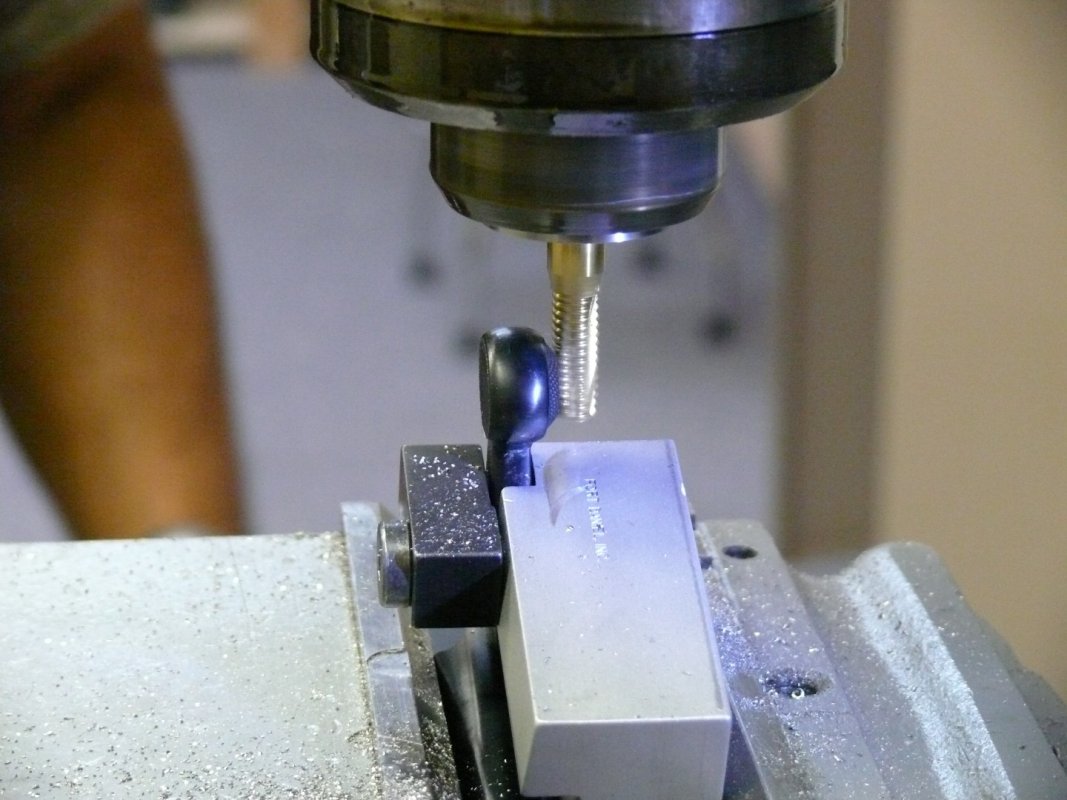

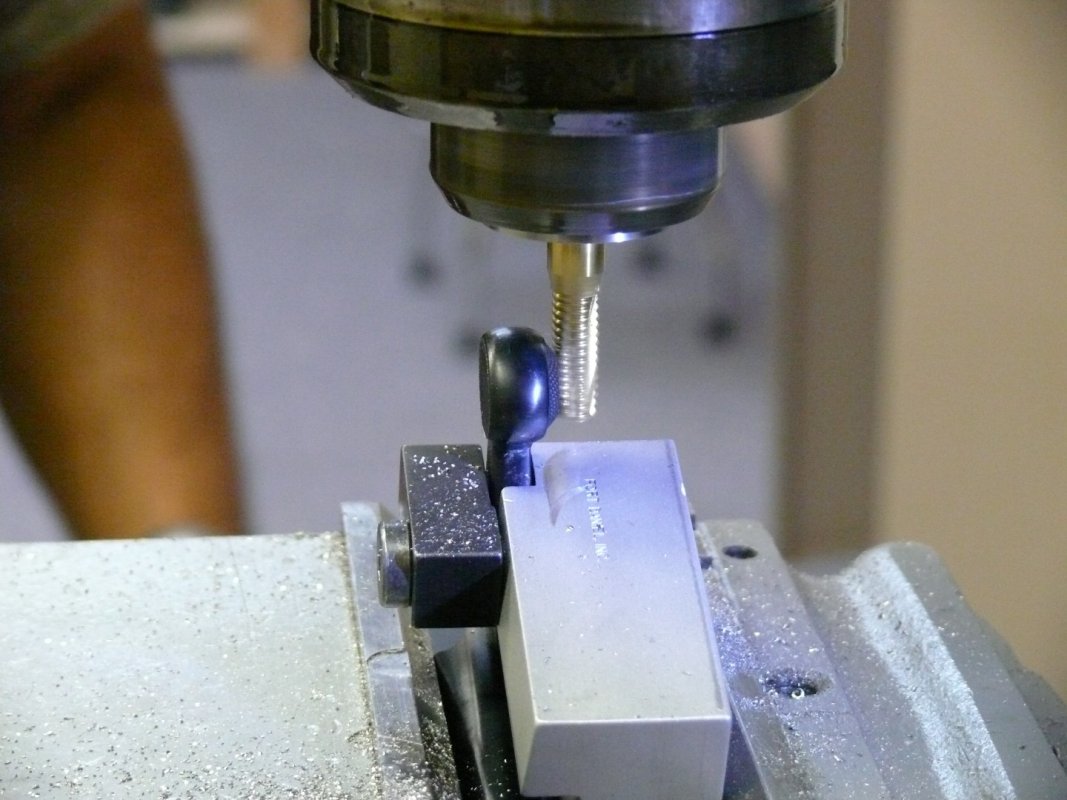

Front of knob cut, working on back now...

A rough square shape is formed and the top milled flat.

Nice rounded square shape now. Anything outside of the circle will be cut away by the hollow mill.

The hollow mill has done its work. Notice nice round shank.

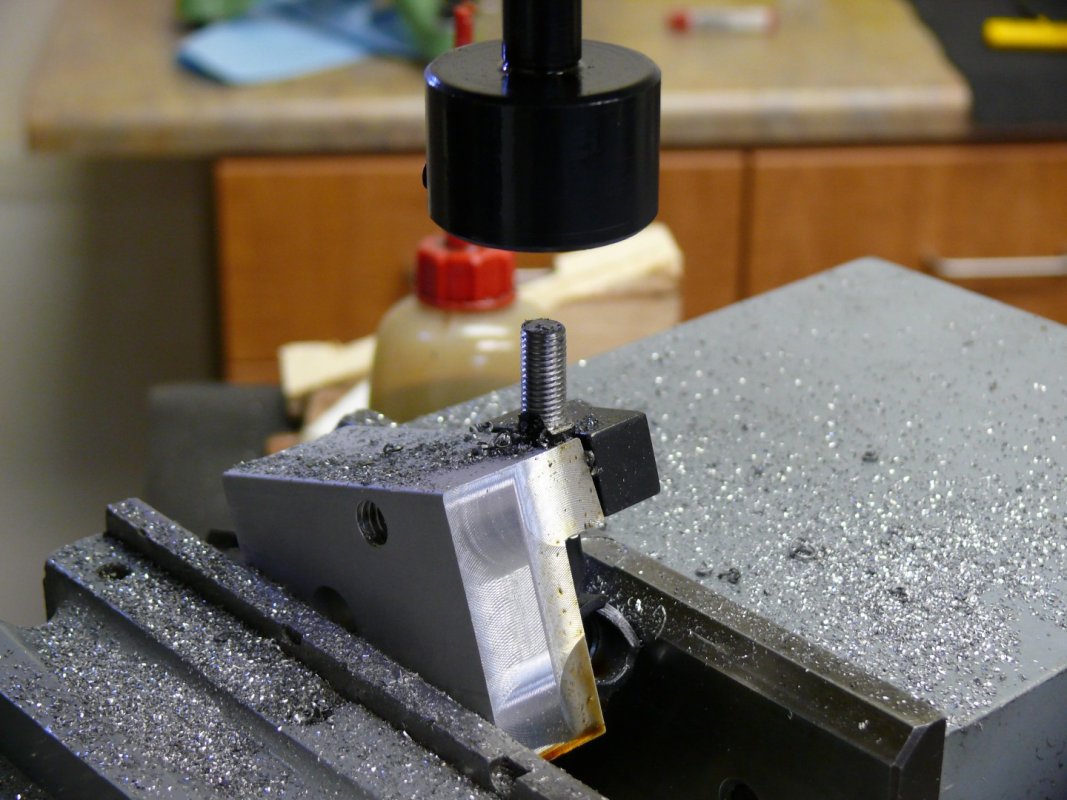

5/16X24 die holder is inserted in milling machine.

All threaded now!

Initial fitting of Ratio Micro bolt knob. A little file work will be done to clean up the edges prior to finish application

In Part II we will true the locking lugs and bolt face. Stay tuned!

The Onyx consists of the following:

Trued and blueprinted Remington 700 action

Shilen 5.5 contour match grade barrel

Timney Trigger

EGW Scope base

Fort Daniel Ratio Micro bolt knob

Bell & Carlson Medalist Tactical stock

Graphite Black Cerakote

In this installment the old bolt knob will be removed and a new Ratio Micro knob will be fitted.

L to R: Bolt, Bolt Takedown Tool, Bolt Holding Fixture, Hollow Mill, 5/16 End Mill

1961 J Series Bridgeport Milling Machine. American Iron!

Bolt and fixture in milling machine vise with angle block that provides a 11 degree sweep for the bolt handle. A straight handle can also be done if the customer requests it.

Front of knob cut, working on back now...

A rough square shape is formed and the top milled flat.

Nice rounded square shape now. Anything outside of the circle will be cut away by the hollow mill.

The hollow mill has done its work. Notice nice round shank.

5/16X24 die holder is inserted in milling machine.

All threaded now!

Initial fitting of Ratio Micro bolt knob. A little file work will be done to clean up the edges prior to finish application

In Part II we will true the locking lugs and bolt face. Stay tuned!