Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

ODT Gun Show & Swap Meet - May 4, 2024! - Click here for info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Primer issue Dillon 650

- Thread starter Jackspack

- Start date

No primer guess. First check to make sure you don’t have any obstructions that keep your rotary primer disc from turning. I find bullets and even primers lodged in all kind of places. Index your machine and see if the wheel is turning every time.

if it still doesn’t work, I would take the primer system off and make sure everything is clean and is working.

Also on the high primers, make sure your primer seater is tight.

if all that doesn’t work post us a video and we will look.

if it still doesn’t work, I would take the primer system off and make sure everything is clean and is working.

Also on the high primers, make sure your primer seater is tight.

if all that doesn’t work post us a video and we will look.

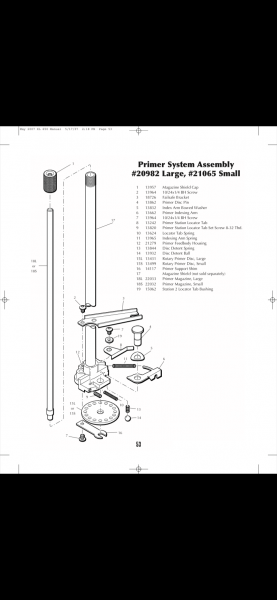

Attachments

I used to watch the primer wheel as the shell plate rotates...just to visually verify ...but now I just do it by feel...I always make sure I have a pronounced upstroke...and feel the primer seat before coming back down...maybe it's something as simple as pronounced full strokes to the very end of the stroke

Make sure that your brass doesn’t have a crimp...

sadly I’ve come across a good bit mixed in my 9mm recently.

sadly I’ve come across a good bit mixed in my 9mm recently.

amen, unless you are sure it is commercial brass.Make sure that your brass doesn’t have a crimp...

sadly I’ve come across a good bit mixed in my 9mm recently.

My techniques-most people do something similar.

Poorly Seated Primer

First : remove shell plate and primer system verify the press is clean.

Second: when reinstalling the shell plate screw, ensure that the shell plate is tightened just enough to prevent the shell plate from tilting upward on the primer station as you seat the primer. Hand tighten the screw all the way down and then back off about a 1/4 turn and verify that it will turn easily by hand and does not have too much wobble. It will always have a little wobble.

Even with everything adjusted correctly, a small amount of carbon or a tight primer pocket will cause a primer to be seated high. Just set the finished bullets with high primer to the side, and run them through the press a second time with out the tool head installed, or run them through a single stage press to complete the primer seating.

The “no primer seated” problem can be a few different issues.

There may not have been a primer in the primer wheel due to filling of the primer tube just a little too late, while continuously loading.

A distraction may cause a short stroke that does not allow the primer wheel to index but does allow the shell plate to rotate.

The primer magazine tube may be dirty or bent or have a bad tip: preventing the primers from falling into the primer wheel. You may need to add a small weight to the top of the primer follow rod-A 45 ACP case fits nicely.

My most dreaded primer problem is actually not related the primer system, but is caused when the shell plate index ring under the platform has cracked. The crack is hard to detect without looking at the ring in motion. You have to pull the press handle with your right hand while bending over to look at index ring. You will be looking to see if the ring appears to expand while rotating, and that it smoothly reverses rotation as the platform is lowered. If it expands or moves in a jerky motion, it is most likely cracked.

When it is cracked, the shell plate may not fully index every time, but will index some of the time before the press gets dirty. You will often get primers that are not fully lining up when they are seated.

This ring cracks when the press is forced through a jam. A high primer can cause a jam that cracks the ring, but not often.

Poorly Seated Primer

First : remove shell plate and primer system verify the press is clean.

Second: when reinstalling the shell plate screw, ensure that the shell plate is tightened just enough to prevent the shell plate from tilting upward on the primer station as you seat the primer. Hand tighten the screw all the way down and then back off about a 1/4 turn and verify that it will turn easily by hand and does not have too much wobble. It will always have a little wobble.

Even with everything adjusted correctly, a small amount of carbon or a tight primer pocket will cause a primer to be seated high. Just set the finished bullets with high primer to the side, and run them through the press a second time with out the tool head installed, or run them through a single stage press to complete the primer seating.

The “no primer seated” problem can be a few different issues.

There may not have been a primer in the primer wheel due to filling of the primer tube just a little too late, while continuously loading.

A distraction may cause a short stroke that does not allow the primer wheel to index but does allow the shell plate to rotate.

The primer magazine tube may be dirty or bent or have a bad tip: preventing the primers from falling into the primer wheel. You may need to add a small weight to the top of the primer follow rod-A 45 ACP case fits nicely.

My most dreaded primer problem is actually not related the primer system, but is caused when the shell plate index ring under the platform has cracked. The crack is hard to detect without looking at the ring in motion. You have to pull the press handle with your right hand while bending over to look at index ring. You will be looking to see if the ring appears to expand while rotating, and that it smoothly reverses rotation as the platform is lowered. If it expands or moves in a jerky motion, it is most likely cracked.

When it is cracked, the shell plate may not fully index every time, but will index some of the time before the press gets dirty. You will often get primers that are not fully lining up when they are seated.

This ring cracks when the press is forced through a jam. A high primer can cause a jam that cracks the ring, but not often.

I willPlease let us know if you figured it out.

Did you ever figure it out? One thing I don’t think was mentioned was calling Dillon and speaking with technical support. You will have to request a call back but they will usually call you in an hour or so.