I could see that. I've had good luck with Beretta. I had to have a ramp polished on an old 950 once. It was used when I got it and somewhere down the line it needed a little helpI had only one issue with the 460 I owned, but was easily resolved. I broke the red loctite on the screw holding the yoke on the gun. That was probably due to some very spicy reloads I made. Wish I hadn't sold that gun, but I'm not willing to pay what they want now for a new one.

Rumors of poor QC are why I just purchased a Ruger GP100 instead of a S&W 686.

As for new guns breaking right away, I have had that experience one time. My first handgun purchase when I turned 21, which was 20 years ago, was a Beretta 96 Brigadier Inox. During the first mag of shooting at the range, the slide release broke off while shooting. Royal pain in the butt trying to get a replacement back then and I didnt consider it worth the time or effort to send it back for such a simple part. Eventually sold that gun to a family member for $100 so I didn't have to deal with it. That piece of junk and the worn out, beat to hell M9s we were issued in the Army really soured me on anything Beretta 92/96.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

ODT Gun Show & Swap Meet - May 4, 2024! - Click here for info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brand New S&W 460 Broke

- Thread starter mattakinbimwalker

- Start date

Well if S&W are having that much trouble, it makes me wonder now what the issues will be with the new Toreasses in 500 and 460.

Might blow up in your faceWell if S&W are having that much trouble, it makes me wonder now what the issues will be with the new Toreasses in 500 and 460.

I'd honestly be a little afraid to shoot one of those. I don't trust their quality that much.Well if S&W are having that much trouble, it makes me wonder now what the issues will be with the new Toreasses in 500 and 460.

With these really powerful firearms, the metallurgy itself becomes really important. Some of that is beyond the manufacturers' direct control.

It's hard to do your own testing on 4150 Stainless Steel as a firearms manufacturer beyond the composition - and maybe some hardness and destructive testing. You can't easily be confident that the billets you had delivered yesterday have the same bulk physical characteristics to the lot you had delivered last month, so to a degree, there's a huge advantage in developing trusted sources. Under 1% of the world's stainless steel is produced in the US. A bit over 6% in Europe. No prizes for working out where almost all of the rest comes from.

This makes sourcing steel you can trust a real challenge. Just like red dots, China is capable of building quality products, but they will supply to a level of quality based on the price point. If Taurus (or Smith & Wesson for that matter) decide to trade off a little of that steel quality for a slightly lower price, at some point, those pigeons come home to roost.

Digression --

I read somewhere that every AR-15 bolt is made using "Carpenter 158" steel - which is not only a specific composition steel, but the manufacturing method also affects the steel, and there's one manufacturer that makes the steel like that, combining hardness, density, crystalline structure etc.

I personally don't believe the claim because you KNOW (and can probably name) companies making AR-15 bolts which are "cheaper and just as good as the ones Colt makes". They Boron Nitride 'em and ship 'em out the door. Some guy buys one, puts it in his new AR and shoots 200 rounds thru' it and shoves it in a closet. Does that reduced 'reliability' actually matter? probably not.

Rant Over.

Fact is, it's possble that a Taurus 500 is made out of steel that is better than the steel used in the Smith. You won't really ever know for sure. Smith and Taurus probably wouldn't either. The difference lies in the support they provide for those products, and that's why the apparent (anecdotal) decline in S&W's CS and QA is significant.

At some point, Taurus might eat S&W's lunch.

It's hard to do your own testing on 4150 Stainless Steel as a firearms manufacturer beyond the composition - and maybe some hardness and destructive testing. You can't easily be confident that the billets you had delivered yesterday have the same bulk physical characteristics to the lot you had delivered last month, so to a degree, there's a huge advantage in developing trusted sources. Under 1% of the world's stainless steel is produced in the US. A bit over 6% in Europe. No prizes for working out where almost all of the rest comes from.

This makes sourcing steel you can trust a real challenge. Just like red dots, China is capable of building quality products, but they will supply to a level of quality based on the price point. If Taurus (or Smith & Wesson for that matter) decide to trade off a little of that steel quality for a slightly lower price, at some point, those pigeons come home to roost.

Digression --

I read somewhere that every AR-15 bolt is made using "Carpenter 158" steel - which is not only a specific composition steel, but the manufacturing method also affects the steel, and there's one manufacturer that makes the steel like that, combining hardness, density, crystalline structure etc.

I personally don't believe the claim because you KNOW (and can probably name) companies making AR-15 bolts which are "cheaper and just as good as the ones Colt makes". They Boron Nitride 'em and ship 'em out the door. Some guy buys one, puts it in his new AR and shoots 200 rounds thru' it and shoves it in a closet. Does that reduced 'reliability' actually matter? probably not.

Rant Over.

Fact is, it's possble that a Taurus 500 is made out of steel that is better than the steel used in the Smith. You won't really ever know for sure. Smith and Taurus probably wouldn't either. The difference lies in the support they provide for those products, and that's why the apparent (anecdotal) decline in S&W's CS and QA is significant.

At some point, Taurus might eat S&W's lunch.

With these really powerful firearms, the metallurgy itself becomes really important. Some of that is beyond the manufacturers' direct control.

It's hard to do your own testing on 4150 Stainless Steel as a firearms manufacturer beyond the composition - and maybe some hardness and destructive testing. You can't easily be confident that the billets you had delivered yesterday have the same bulk physical characteristics to the lot you had delivered last month, so to a degree, there's a huge advantage in developing trusted sources. Under 1% of the world's stainless steel is produced in the US. A bit over 6% in Europe. No prizes for working out where almost all of the rest comes from.

This makes sourcing steel you can trust a real challenge. Just like red dots, China is capable of building quality products, but they will supply to a level of quality based on the price point. If Taurus (or Smith & Wesson for that matter) decide to trade off a little of that steel quality for a slightly lower price, at some point, those pigeons come home to roost.

Digression --

I read somewhere that every AR-15 bolt is made using "Carpenter 158" steel - which is not only a specific composition steel, but the manufacturing method also affects the steel, and there's one manufacturer that makes the steel like that, combining hardness, density, crystalline structure etc.

I personally don't believe the claim because you KNOW (and can probably name) companies making AR-15 bolts which are "cheaper and just as good as the ones Colt makes". They Boron Nitride 'em and ship 'em out the door. Some guy buys one, puts it in his new AR and shoots 200 rounds thru' it and shoves it in a closet. Does that reduced 'reliability' actually matter? probably not.

Rant Over.

Fact is, it's possble that a Taurus 500 is made out of steel that is better than the steel used in the Smith. You won't really ever know for sure. Smith and Taurus probably wouldn't either. The difference lies in the support they provide for those products, and that's why the apparent (anecdotal) decline in S&W's CS and QA is significant.

At some point, Taurus might eat S&W's lunch.

The good AR bolts are made of C-158.

Many manufacturers nowadays use 9310, which is inferior to C-158 in that application. Why use 9310 instead? Much easier and cheaper to source than C-158.

LMT uses AerMet 100 in their E-Bolts. This is a case of using a material that greatly exceeds the specs needed for the application. They’re f’ing fantastic, but a valid argument can be made that AerMet 100 is gross overkill in that application. I have one in my primary AR, and it didn’t make it run any better or worse, although the argument can be made that when only used for semi-auto firing rates it will never need replaced.

I had a Remlin .444 catastrophically fail after the 2nd shot using standard pressure Hornady ammo. What a disappointment that was, waiting months for repair turn around turned me off from the brand entirely. I'm tempted again now that Ruger is running the show. I don't think I could ever trust the .460 again if I were you, especially if it is serving as defense against large dangerous critters in the field.

I had a Remlin .444 catastrophically fail after the 2nd shot using standard pressure Hornady ammo. What a disappointment that was, waiting months for repair turn around turned me off from the brand entirely. I'm tempted again now that Ruger is running the show. I don't think I could ever trust the .460 again if I were you, especially if it is serving as defense against large dangerous critters in the field.

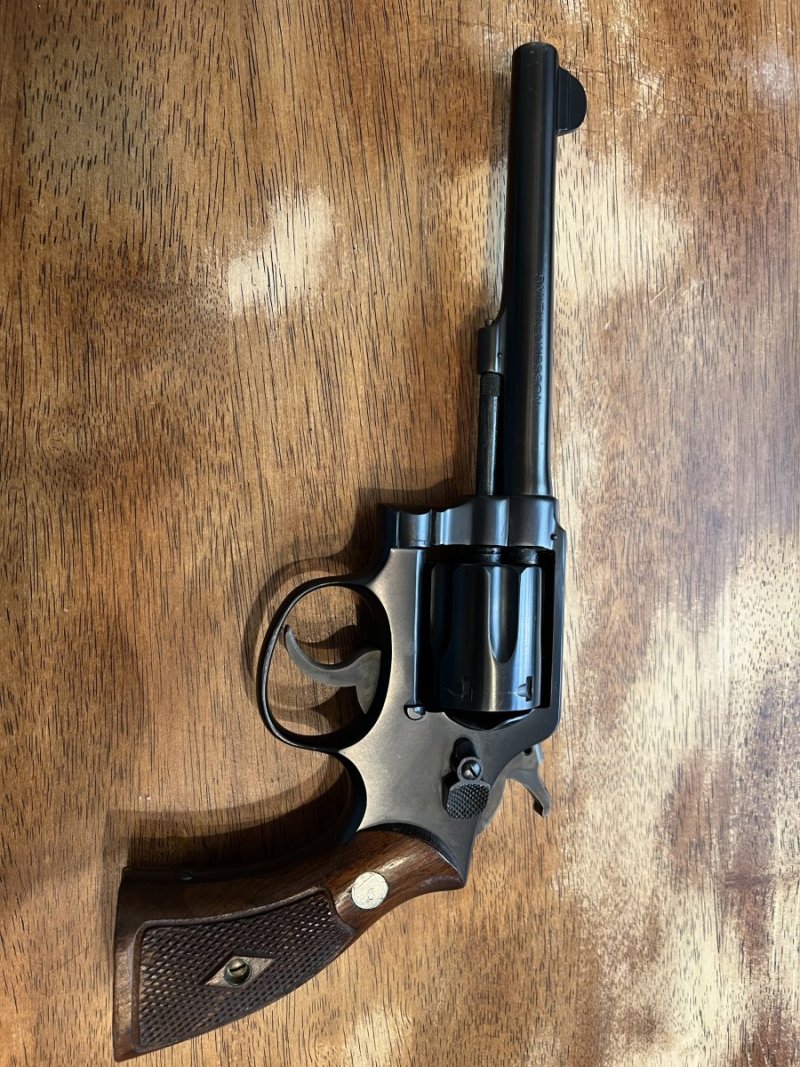

It definitely gets in the back of your mind. Funny thing is my everyday carry is a full sized Smith 1911 45ACP and has been for 15 years. It has been the most reliable carry gun I have. I can put rounds in the same hole with it consistently. I had a 629 Classic Smith that was amazing and it was a used gun that had seen a ton of use. I have a Model 29 thats perfect also. The 460 was just an oddity. I never expected it to crap out after 2 rounds. Just goes to show you....new doesn't always mean better.

I have had four Smith 460's (different barrel lengths) a 4" 500 for several years. Never had a problem except for the cost of the ammo. Remember to clean the cylinders really good after firing 45s and 454s to keep the 460 cases from sticking. Great guns.

I have to admit my S&W experience has been stellar. I also believe the X frame to be a specialty item. With the reputation S&W has at least with me, I can't believe they would put something out that would fail like that. I think it all comes back to today's quality control. I've owned many S&Ws over the years and only had one hand spring fail. And that pistol was abused before I got it.It definitely gets in the back of your mind. Funny thing is my everyday carry is a full sized Smith 1911 45ACP and has been for 15 years. It has been the most reliable carry gun I have. I can put rounds in the same hole with it consistently. I had a 629 Classic Smith that was amazing and it was a used gun that had seen a ton of use. I have a Model 29 thats perfect also. The 460 was just an oddity. I never expected it to crap out after 2 rounds. Just goes to show you....new doesn't always mean better.