Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

ODT Gun Show & Swap Meet - May 4, 2024! - Click here for info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

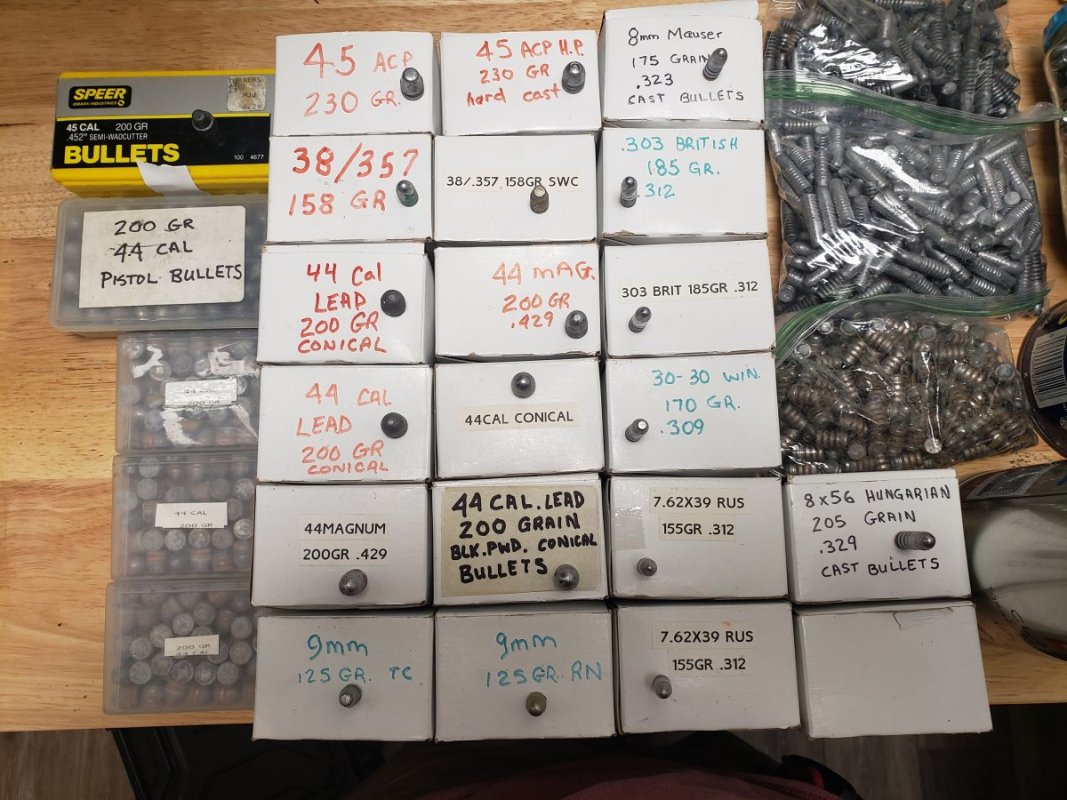

Made one of these

- Thread starter Quacker

- Start date

So would this be used after the brass is resized? Nice work.

Yes. I have a lot of 5.56 blank brass I’m planning to convert to 300 blkSo would this be used after the brass is resized? Nice work.

Looking good.I love repurposing and saving brass.Keep us updated.

That's brilliant, are you posting a make somewhere?

I'm in process of making a powder measure and scale, automated. Set the target charge weight and it'll extrude the right amount of powder into the cup. Uses Arduino, a load cell, LED screen and a bunch of 3d printed parts. I'll post a make thread with video when it's running. Waiting for a couple more electronic parts to ship in.

That’s awesome! Definitely in for a build thread on that!I'm in process of making a powder measure and scale, automated. Set the target charge weight and it'll extrude the right amount of powder into the cup. Uses Arduino, a load cell, LED screen and a bunch of 3d printed parts. I'll post a make thread with video when it's running. Waiting for a couple more electronic parts to ship in.

naw just sharing pics for the moment. There are plenty of diy case annealer tutorials out there plus I don’t have the time these days

Before sizing. The point is to soften the brass equally then work harden it equally. Also, not sure how much warpage 700F would induce in a ready to load case mouth.So would this be used after the brass is resized? Nice work.

However, for the OP conversion process it's done for the additional reason of softening what is thicker and harder brass in the previous 223 case body.

A must have item for case conversions and optimal accuracy. I bought mine from annealeez. Added some upgrades and works great. Really want an AMP though.