This is supposed to be a lousy mold for a Glock with stock barrel, but not for mine. I’m sure some have leading and keyholing...that many people can’t be making it up. I might have got lucky, but no issues at all with the 45-45-10 lube. I thought it would look like a **** bomb went off with all the talk about how messy it was. Didn’t happen. Seater needs cleaning after 300 or so, but no big deal really. I can’t see powder coating them as it it would be way more laborious and a fix to a problem that is nonexistent in my case.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

ODT Gun Show & Swap Meet - May 4, 2024! - Click here for info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

bullet casters

- Thread starter buellbrewer

- Start date

- Joined

- Oct 1, 2010

- Messages

- 7,024

- Reaction score

- 9,462

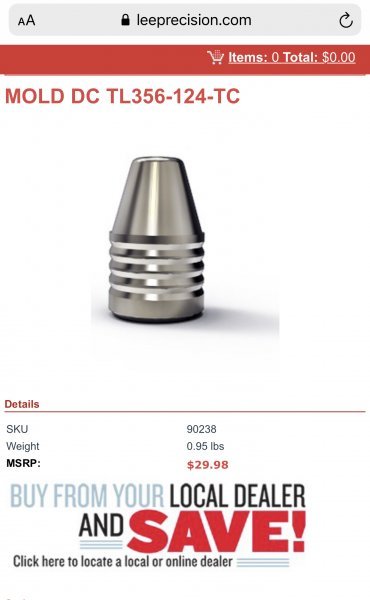

I just cast 10lbs worth of that 125gr. .358 bullet out of a 6 cav the other day. I'm curious to see how it does. That 200gr. .45 mold is a good one.

- Joined

- Oct 1, 2010

- Messages

- 7,024

- Reaction score

- 9,462

This is supposed to be a lousy mold for a Glock with stock barrel, but not for mine. I’m sure some have leading and keyholing...that many people can’t be making it up. I might have got lucky, but no issues at all with the 45-45-10 lube. I thought it would look like a **** bomb went off with all the talk about how messy it was. Didn’t happen. Seater needs cleaning after 300 or so, but no big deal really. I can’t see powder coating them as it it would be way more laborious and a fix to a problem that is nonexistent in my case.

The whole "no lead in stock Glock barrels" is nonsense. Shoot away and enjoy.

I just cast 10lbs worth of that 125gr. .358 bullet out of a 6 cav the other day. I'm curious to see how it does. That 200gr. .45 mold is a good one.

Heres hoping. I just got a small amount of WW on the way home today from the mom and pop shop and am hoping to do a small batch of 9mm and 45 this weekend once I clean it up. I’m trying to keep building up a bit of lead along as I can... but have stuck to local sources thus far. I have over 50 lbs I’m sure... but probably shy of 100. Lucked out on 25 lbs of 50-50 solder to have a pile of tin. Gotta get those rookie lead numbers up though!

My 9mm dies arrived yesterday and I just snagged a 45 die when it was in stock after I got home from work today. It’s all starting to come together. I’ll have to check and see if I can use the 9mm die for .380 like .38 and .357. Not sure if one is a straight wall vs taper. It’d be neat to load some of those 105 SWCs in a .380 for fun. I bought my mom a PK380 Walther some years back and it’d be neat to load up something for her. She’s well in her 70s and never taken to guns as a hobby but does like shooting a bit to keep her confidence up. Given her limited practice, she’s shockingly proficient. Calm nerves gives way to steady hands I suppose.

Welp. I guess I’m going to melt down the 50-100 358-158-RFs I had left over from trying to load them w/Unique and try again. They leased up pretty bad after I sized them down to .358. Barrel slugs at .357 and they dropped at .359 or so.

They weight out at 160.3 give or take a couple tenths. Only thing that seems wonky is that they’re *stupid* hard. I have a set of pencils that go up to 4H. That’s something around 30 BHN... and it won’t mark the bullet. I did water quench but mainly did that out of the convenience of not having piping hot bullets hanging out cooling. Best I can guess is they’re just too damn hard... I under lubed... or all of the above. I had to go get some of those copper scrubbies to clean the lead out. I sure don’t want to do that again. Been reading up on cast bullets for awhile tonight... but just don’t get how my bullets got that hard. WW lead with a bit of tin for fill out with a pinch of scrap.

They weight out at 160.3 give or take a couple tenths. Only thing that seems wonky is that they’re *stupid* hard. I have a set of pencils that go up to 4H. That’s something around 30 BHN... and it won’t mark the bullet. I did water quench but mainly did that out of the convenience of not having piping hot bullets hanging out cooling. Best I can guess is they’re just too damn hard... I under lubed... or all of the above. I had to go get some of those copper scrubbies to clean the lead out. I sure don’t want to do that again. Been reading up on cast bullets for awhile tonight... but just don’t get how my bullets got that hard. WW lead with a bit of tin for fill out with a pinch of scrap.

Welp. I guess I’m going to melt down the 50-100 358-158-RFs I had left over from trying to load them w/Unique and try again. They leased up pretty bad after I sized them down to .358. Barrel slugs at .357 and they dropped at .359 or so.

They weight out at 160.3 give or take a couple tenths. Only thing that seems wonky is that they’re *stupid* hard. I have a set of pencils that go up to 4H. That’s something around 30 BHN... and it won’t mark the bullet. I did water quench but mainly did that out of the convenience of not having pipijustng hot bullets hanging out cooling. Best I can guess is they’re just too damn hard... I under lubed... or all of the above. I had to go get some of those copper scrubbies to clean the lead out. I sure don’t want to do that again. Been reading up on cast bullets for awhile tonight... but just don’t get how my bullets got that hard. WW lead with a bit of tin for fill out with a pinch of scrap.

You probably got some wheelweights made out of pot metal/zinc. Just a little zinc will harden them up to where you can't work them.

Water quenching won't make them that hard. Also explains the leading that was so hard to remove.

You probably got some wheelweights made out of pot metal/zinc. Just a little zinc will harden them up to where you can't work them.

Water quenching won't make them that hard. Also explains the leading that was so hard to remove.

Possibly. I’d though the same thing and I was reading up a lot last night thinking the same thing. There was nothing else “floating” that made me think there was zinc in the mix and I have a thermometer to back me up to keep my pot cool enough to not melt zinc... plus I hand sort before I make ingots... so I’m just not sure. The pot looked great, the weight is spot on and I did add some hardcast bullet scrap to the pot plus water quench... so maybe a bit extra antimony that the WQing worked in a bit. I figured zinc bullets would cast light but my 158s dropped at a smidge over 160. The lead wasn’t terribly hard to get out, but I got the copper pad to not have to fool around with it. I’m going to mix in some softer lead muffins I have and just try again and not water quench next time and see how it goes. Still learning!

Well, I snagged one of these earlier this week. I’ll eventually use it to try out powder coating. In the meantime, I’m going to see if I can undo the water quench hardness and get the small batch of 158 gr 358 RFs down in the upper teens/low 20s. On all my reading I’ve seen WC hardness ranging from upper teens to the 30s... with the big variables being antimony/arsenic content and the temperature in which you dropped the bullets being another huge factor. I know I dropped them very hot... just cool enough for the sprue to harden and they hit the water well over boiling hot still. It’ll be an interesting experiment to see how it affects them. The next batch won’t be water quenched... and I may try for them this weekend if I get around to it. This’ll be an easy set-and-forget for a handful of bullets that I can take my artist pencils to in order to see a hardness change.

Good looking oven to pc in. When you pc you will heat the boolit to 200 degrees then let cool naturally that will drop the hardness a little. With a new pc oven check the temp with a thermometer first. I set mine to 200 and popped in about 100 9mm and they all slumped over.Well, I snagged one of these earlier this week. I’ll eventually use it to try out powder coating. In the meantime, I’m going to see if I can undo the water quench hardness and get the small batch of 158 gr 358 RFs down in the upper teens/low 20s. On all my reading I’ve seen WC hardness ranging from upper teens to the 30s... with the big variables being antimony/arsenic content and the temperature in which you dropped the bullets being another huge factor. I know I dropped them very hot... just cool enough for the sprue to harden and they hit the water well over boiling hot still. It’ll be an interesting experiment to see how it affects them. The next batch won’t be water quenched... and I may try for them this weekend if I get around to it. This’ll be an easy set-and-forget for a handful of bullets that I can take my artist pencils to in order to see a hardness change.

View attachment 3212007

Good looking oven to pc in. When you pc you will heat the boolit to 200 degrees then let cool naturally that will drop the hardness a little. With a new pc oven check the temp with a thermometer first. I set mine to 200 and popped in about 100 9mm and they all slumped over.

Thanks for the advice! I checked my local Harbor Freight as I’d heard their house brand red was a decent PC to try but all they had on the shelf was white and black and didn’t know if the color made any difference to it’s performance. Heard good stuff about Eastman (? East-something). Figure I’d like try something. I haven’t had any leading issues until the other day. I do like the idea of eventually getting a lever gun and pushing some .357 at speeds I think would require something more than Alox would give me. And... well... it’s just a fun thing to tinker with

What PC do/have you used and had luck with?

Similar threads

- Replies

- 10

- Views

- 495