Could use some help ODT. I've recently gotten into 3D printing with an Ender 3V2. Started with printing off a few models I found online. Printing a Glock mount I found on Thingaverse...put it in TinkerCAD and flipped it the other direction then printed in ABS without any issues (I have a thermal lined enclosure). I decided to take that file and alter the dimensions in TinkerCAD to make a mount for my Glock 40 10MM long slide.

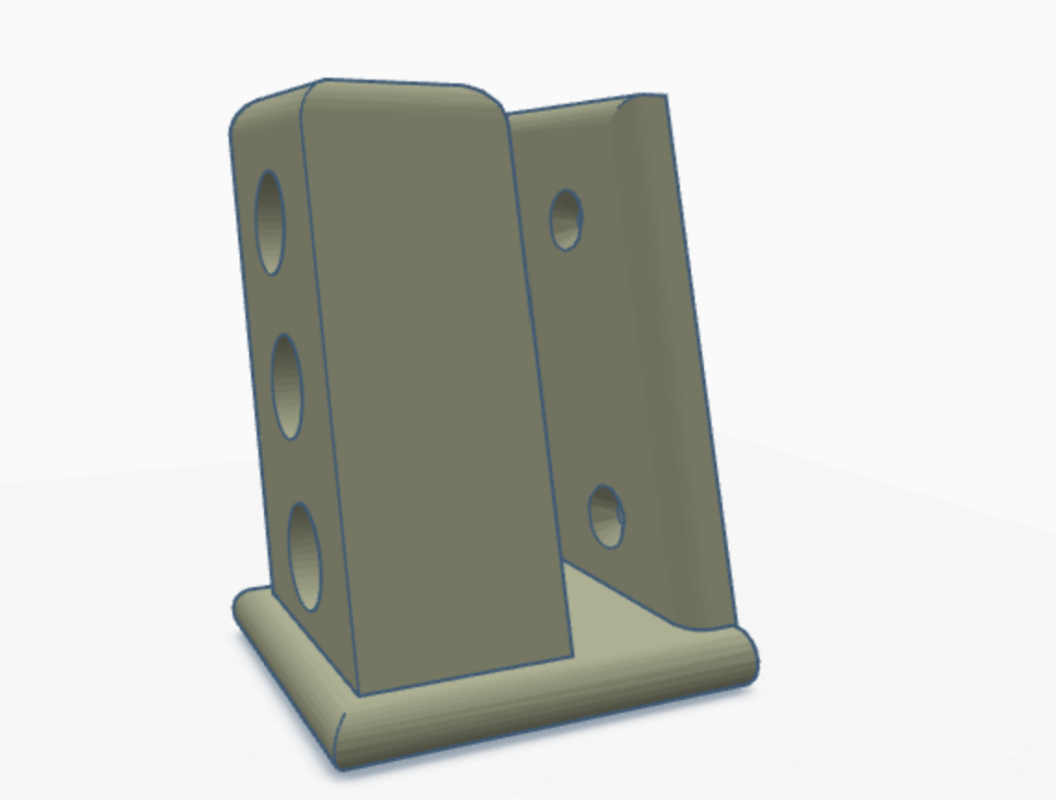

To do this, I essentially broke the original piece into 3 pieces: the vertical plane that mounts to the wall, the bottom plane, and the larger piece that goes into the magwell. The magwell piece is the one I most wanted to enlarge so there was less play when inserting it in the 10MM's larger magazine area. I did this, lined the 2 vertical planes up to the bottom plane, grouped them back together, exported the file to Cura and then printed the file.

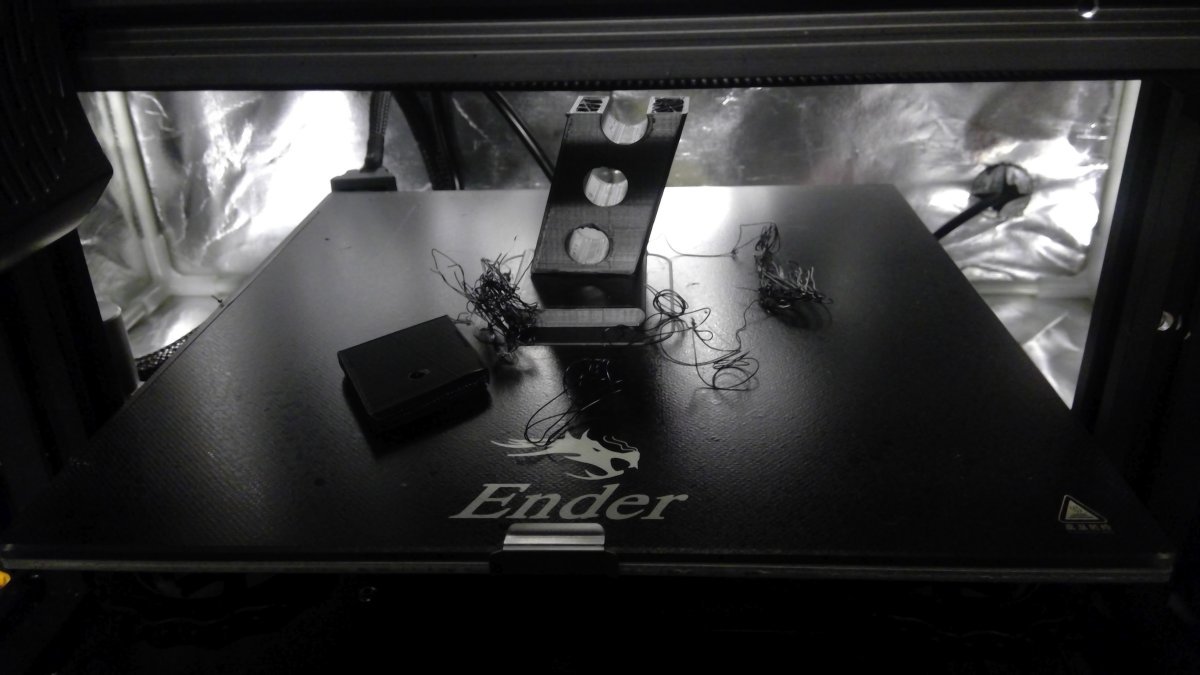

I checked on it every so often then noticed I had a problem a few hours into the print. The smaller vertical plane that attaches to the wall had fallen over so it was trying to lay filament into unsupported space. I stopped the print and when I tried to take the print off the bed, the larger vertical magazine piece came off the bottom plane very easily. I've included a few files of the design as well as the failed results. The second picture is the top of the horizontal plane and the bottom of the mag insert that was supposed to be attached to it.

So what did I do wrong? Should I have recessed the vertical planes 1MM into the horizontal plane before grouping them? Was it some setting in Cura that I should have done differently? I appreciate the help!